| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : ROYAL

Model Number : RTSP1616

Certification : CE certification

Place of Origin : Made in China

MOQ : 1 set

Price : negotiable

Payment Terms : L/C, D/A, D/P, T/T

Supply Ability : 15 sets per month

Delivery Time : 12 weeks

Packaging Details : Export standard, to be packed in new cases/cartons, suitable for long-distance ocean/air and inland transportation.

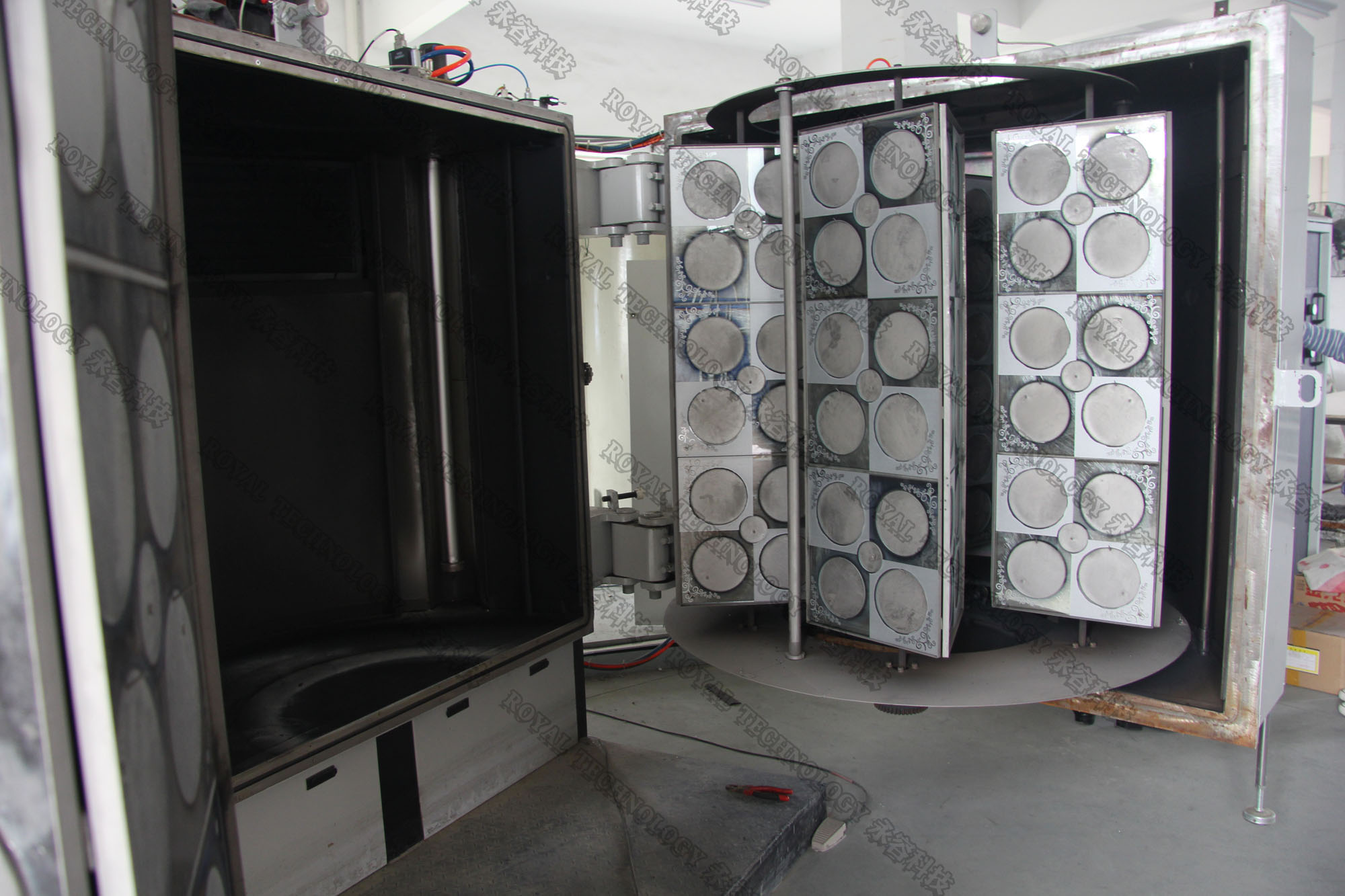

Chamber : Vertical Orientation, 2-doors,

Vacuum Technology : DC Sputtering Deposition

Deposition Sources : Planar/ Cylindrical Sputtering Cathode

Coating Films : Al, Ag, Cr, Cu, Ti, Stainless Steel high reflection films

Factory Location : Shanghai city, China

Worldwide Service : Poland - Europe; Iran- West Asia & Middle East, Turkey, India, Mexico- South America

Training Service : Machine operation, maintenance, coating process Recipes, program

Warranty : Limited warranty 1 year for free, whole life for machine

OEM & ODM : available, we support tailor made design and fabrication

DC Magnetron Sputtering Coating Machine on Glass Mirrors , Titanium Ti Glass Mirror Vacuum Metallizing Equipment

DC Sputtering Metallizer on Glass Mirrors, Titanium Ti Glass Mirror Vacuum Metallizing Equipment, Ti Sputtering Coater

I. Equipment Introduction:

Compared with Thermal evaporation metalizing method, the DC Sputtering coater saves lots time on the deposition sources and coating materials exchange, which highly improve the productivity.

| MODEL | RTSP1616-DC | ||

| MATERIAL | Stainless Steel (S304) | ||

| CHAMBER SIZE | Φ1600*1600mm (H) | ||

| PUMP SYSTEM | Rotary Piston Vacuum Pump | ||

| Rotary Vane Vacuum Pump | |||

| Roots Vacuum Pump | |||

| Diffusion Pump | |||

| TECHNOLOGY | Magnetron Sputtering Coating | ||

| CONTROL | PLC(Programmable Logic Controller) + Touch Screen | ||

| GAS | Gas Mass Flow Meters | ||

| SAFETY SYSTEM | Numerous safety interlocks to protect operators and equipment | ||

| COOLING | Water | ||

| CLEANING | Ion Source | ||

| POWER MAX. | 145KW | ||

| AVERAGE POWER CONSUMPTION | 70KW | ||

Advantages of this machine(vacuum PVD coater):

1) Simple visual interface for the operator, process control system runs on Windows system interface and easy to use

2) Vacuum pump system efficiency, which increases productivity due to shorter batch times

3) High performance layer monitoring system is equipped for enhanced production result

4) Automated work cycle, which requires less workers per shift and training time, low production cost

5) Repeatable and reliable coating

6) Safter and Environmentally-friendly process guarantee

7) Highest yield

Coating properties:

• Excellent layer properties

• Longer lifetime

• Smooth surface

• Many bright, metallic colours, decorative or functional

• Excellent scratch protection

tag words:

Aluminum Al glass coating machine , Chrome Cr mirror coating equipment , high reflection glass mirror metallizing plant

Please contact us for more specifications, Royal Technology is honored to provide you total coating solutions.

|

|

DC Magnetron Sputtering Coating Machine on Glass Mirrors , Titanium Ti Glass Mirror Vacuum Metallizing Equipment Images |