| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : ROYAL TECHNOLOGY

Model Number : RTSP1480

Certification : CE

Place of Origin : MADE IN CHINA

MOQ : 1

Price : negotiable

Payment Terms : L/C, T/T

Supply Ability : 5 SETS/MONTH

Delivery Time : 6 months

Packaging Details : Export standard, to be packed in new cases/cartons, suitable for long-distance ocean/air and inland transportation.

Applications : Conductive metal wiresMetal coil and metal strip with thickness is less than 1mm Optical fiber Twisted fiber and wires such as basalt fiber (BFRP) and carbon fiber, glass yarns, carbon yarns

Sputtering Films : Ag Silver, Aluminum, Copper, Chrome, Ni Nickle

Technology : Magetron sputtering + Ion Beam Plasma + Roll to Roll winding system

Factory Location : Shanghai city, China

Worldwide Service : Poland - Europe; Iran- West Asia & Middle East, Turkey, India, Mexico- South America

Training Service : Machine operation, maintenance, coating process Recipes, program

Warranty : Limited warranty 1 year for free, whole life for machine

OEM & ODM : available, we support tailor made design and fabrication

Turkey Coating Solutions, knows-how to transfer technology.

9- RTSP1480- air to air -continuous line- metal wi... Please download catalogue here

Application

Technical Background

After decades of research and development, vacuum coating has been quite a mature film deposition treatment which has a positive prospect applications in various industries. It requires a comprehensive technologies to apply the vacuum coating technique to continuous wires and strips, which can modify the surface characteristics and functions, its significant lightweight performance makes an advantage for artificial intelligence devices.

Types of the existing vacuum coating production line for wires and strips substrates

(1)Separated type

(2) Air-to Air,full continuous coating type

The Air-to Air full continuous coating line is a completed continuous coating process processes which including cleaning pre-treatment in the atmosphere environment, and then the substrates ( strips or wires) enters into the vacuum chamber to get metal films deposited, in then end it back to atmosphere environment again through buffering chambers.

The coating line key structural modules:

A: Substrates (strips or wires) cleaning pre-treatment module

B: Cooling down module

C: Annealing module

D: Film deposition chamber

E: Loop devices and vacuum buffering chamber.

The whole coating line’s structure, operation and control system is more complex, extremely high investment but the advantages of high output and sharping down production cost efficiently make it is very attractive for manufacturers.

Technical Discussion

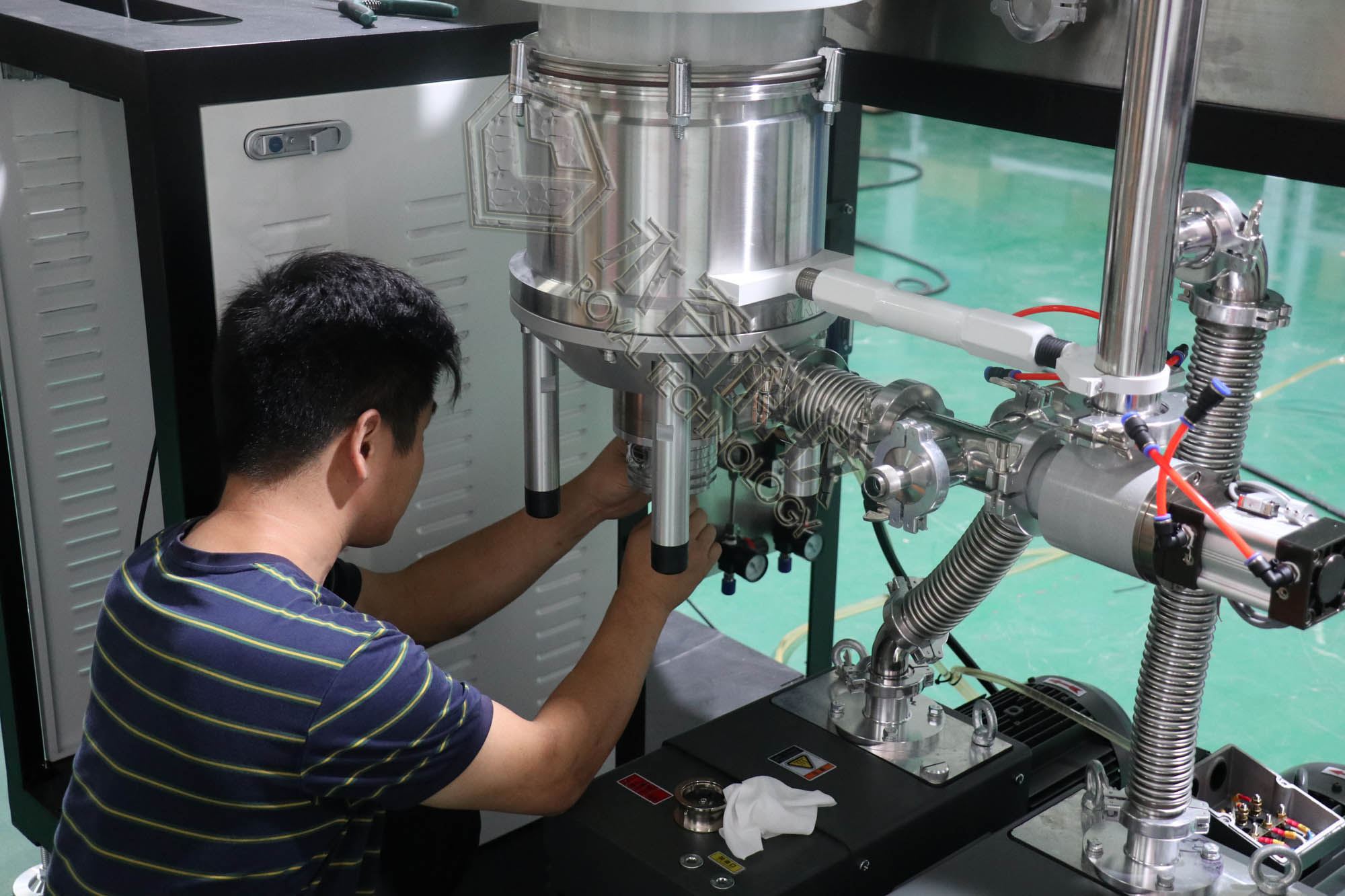

Installation and Quality Inspection

Installation and Commissioning in Customer's site

(3)Universal Type

(4) Multiple-layers coating type

The production line combine several different PVD coating methods: Electron beam evaporation coating, magnetron sputtering deposition and plasma enhanced CVD deposition.

Royal technology’s team has built the pilot system for industrial production line in 2019.

we are excited to announce that outsourcing coating service to us is available now.

Please contact us who is interested in the coating system, turnkey coating solution can be provided.

|

|

Air-To-Air Continuous Sputtering Deposition Line for Glass Yarns And Carbon Yarns Copper Coating Images |